- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High-Bay Stacker Crane Applications & Uses

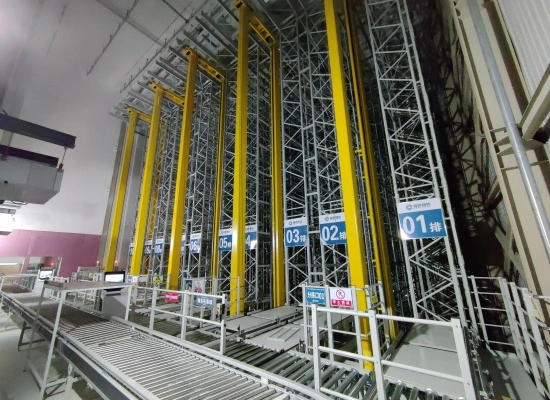

The High-Bay Stacker Crane speaks to a foundation innovation in present day robotized distribution center frameworks, outlined to maximize vertical capacity capacity whereas keeping up remarkable operational productivity. These modern computerized frameworks serve as the spine of high-density capacity offices, competent of coming to amazing statures up to 45 meters whereas taking care of loads extending from lightweight components of 5 kg to overwhelming mechanical materials weighing up to 10 tons. The flexibility and accuracy of High-Bay Stacker Crane innovation make it crucial over different businesses counting development apparatus, chemicals, pharmaceuticals, fast-moving customer products, metals, and car segments, where effective space utilization and quick stock administration are basic for operational success.

Industrial Applications of High-Bay Stacker Cranes

Construction Machinery and Heavy Equipment Storage

The development apparatus industry benefits massively from High-Bay Stacker Crane executions due to the system's extraordinary load-carrying capacity and tallness availability. These cranes productively oversee the capacity and recovery of overwhelming development components, save parts, and apparatus congregations that require specialized dealing with strategies. The capacity to reach statures of 16 meters with uncommon execution guarantees that important distribution center space is maximized whereas keeping up simple get to to basic gear components. Development apparatus stockrooms utilize these frameworks to organize stock based on request recurrence, with as often as possible gotten to things situated at ideal statures for speedy recovery. The customizable nature of High-Bay Stacker Crane frameworks permits for adjustments to suit shifting component sizes and weights, making them perfect for putting away everything from little pressure driven components to expansive motor gatherings and basic elements.

Chemical and Pharmaceutical Industries

Chemical and pharmaceutical applications demand the highest levels of precision, safety, and contamination control, making High-Bay Stacker Crane systems essential for these regulated environments. The crane's ability to operate in controlled atmospheres while maintaining strict safety standards ensures compliance with industry regulations and quality requirements. Pharmaceutical warehouses leverage the system's precise positioning capabilities to maintain proper storage conditions for temperature-sensitive medications and ensure accurate inventory tracking for regulatory compliance. The integration of fire extinguishing mechanisms within the loading platform addresses safety concerns specific to chemical storage, where rapid response to potential hazards is crucial. The low energy consumption design, which achieves a 30% year-over-year reduction in energy usage, is particularly valuable in pharmaceutical environments where operational costs directly impact product pricing and market competitiveness.

Fast-Moving Consumer Goods and Automotive Sectors

The fast-moving consumer goods industry relies on High-Bay Stacker Crane technology to manage high-velocity inventory turnover while maintaining accuracy in order fulfillment. These systems excel in environments where rapid access to diverse product lines is essential for meeting customer demand and maintaining competitive delivery schedules. The crane's exceptional speed and efficiency capabilities enable warehouse operations to handle peak demand periods without compromising accuracy or safety. Automotive applications benefit from the system's ability to manage complex parts inventories with varying sizes and weights, supporting just-in-time manufacturing processes that minimize inventory holding costs. The customizable storage management features allow automotive warehouses to optimize parts placement based on production schedules and seasonal demand patterns, ensuring that critical components remain readily accessible while maximizing overall storage density.

Technical Features and Performance Capabilities

Advanced Height and Load Management Systems

Modern High-Bay Stacker Crane systems incorporate sophisticated engineering solutions that enable safe and efficient operations at extreme heights while handling diverse load requirements. The crane's structural design utilizes high-strength materials and precision manufacturing techniques to ensure stability and reliability when operating at maximum height and load capacities. Advanced control systems continuously monitor load distribution and crane positioning to prevent operational hazards and ensure optimal performance across all operating conditions. The system's ability to handle loads ranging from 5 kg to 10 tons requires sophisticated mechanical and electrical components that can adapt to varying operational demands without compromising speed or accuracy. Height management capabilities extend beyond simple vertical movement, incorporating intelligent positioning algorithms that optimize travel paths and minimize cycle times while maintaining safety protocols.

Energy Efficiency and Environmental Impact

The emphasis on low energy consumption represents a significant advancement in High-Bay Stacker Crane technology, addressing both operational cost concerns and environmental sustainability requirements. The 30% reduction in energy consumption achieved through optimized design elements includes efficient motor systems, regenerative braking capabilities, and intelligent power management algorithms that adjust energy usage based on operational demands. This energy efficiency improvement translates to substantial cost savings over the system's operational lifetime while reducing the environmental footprint of warehouse operations. The design incorporates lightweight materials and efficient mechanical systems that minimize energy requirements during acceleration, deceleration, and positioning operations. Energy recovery systems capture and reuse energy from descending movements, further contributing to overall efficiency improvements and operational cost reductions.

Safety Standards and Compliance Features

High-Bay Stacker Crane systems must meet stringent safety requirements due to their operational complexity and potential hazards associated with high-altitude operations and heavy load handling. Compliance with national, military, and European safety standards ensures that these systems can operate safely in diverse regulatory environments while protecting personnel and equipment. TÜV CE certification validates adherence to the latest EU EN528 and PLd electrical safety regulations, demonstrating the system's commitment to international safety standards. The integration of multiple safety mechanisms includes emergency stop systems, load monitoring capabilities, and collision avoidance technologies that prevent accidents and equipment damage. Comprehensive safety features extend to maintenance operations, with multiple maintenance platforms and user-friendly manual operation modes that enable safe inspection and servicing procedures at various system locations.

Maintenance and Operational Advantages

User-Friendly Maintenance Infrastructure

The design philosophy behind modern High-Bay Stacker Crane systems emphasizes accessibility and ease of maintenance to minimize operational downtime and reduce long-term maintenance costs. User-friendly manual operation modes provide maintenance personnel with direct control capabilities during servicing procedures, ensuring safe and efficient maintenance operations. The availability of mobile control boxes and distributed inching control buttons enables precise positioning and movement control during maintenance activities, allowing technicians to access all system components safely. Multiple maintenance platforms strategically positioned throughout the crane structure facilitate comprehensive equipment inspection and maintenance procedures without requiring additional lifting equipment or safety apparatus. This maintenance-focused design approach reduces the total cost of ownership while ensuring consistent operational availability and system reliability.

Customization and Adaptability Features

The characteristic adaptability of High-Bay Stacker Crane frameworks permits for broad customization to meet particular operational necessities and distribution center setups. Customizable capacity administration capabilities empower optimization of stock arrangement methodologies based on item characteristics, request designs, and operational workflows. The stacking platform's secluded plan licenses alterations and overhauls to suit changing operational prerequisites or modern item lines without requiring total framework substitution. Industry-specific customizations incorporate specialized dealing with connections, natural controls, and security highlights custom-made to particular applications such as cleanroom operations or unsafe fabric taking care of. This versatility guarantees that High-Bay Stacker Crane ventures stay profitable as trade necessities advance and operational requests alter over time.

Integration with Warehouse Management Systems

Seamless integration capabilities enable High-Bay Stacker Crane systems to function as integral components of comprehensive warehouse management ecosystems. Advanced communication protocols facilitate real-time data exchange between the crane control systems and warehouse management software, enabling optimized task assignment and inventory tracking. The system's ability to provide detailed operational data supports predictive maintenance strategies and performance optimization initiatives that improve overall warehouse efficiency. Integration features include compatibility with existing warehouse management systems, support for multiple communication standards, and flexibility to accommodate future technology upgrades. This connectivity ensures that High-Bay Stacker Crane systems can evolve alongside advancing warehouse technologies while maintaining operational continuity and data consistency across all warehouse operations.

Conclusion

High-Bay Stacker Crane innovation conveys transformative benefits over differing mechanical applications through its combination of noteworthy tallness capabilities, flexible stack taking care of, vitality productivity, and comprehensive security highlights. From development apparatus to pharmaceuticals, these frameworks optimize stockroom operations whereas assembly rigid industry necessities and administrative standards.

As a trusted High-Bay Stacker Crane provider and experienced High-Bay Stacker Crane producer, Fortucky brings decades of mastery to the worldwide cleverly fabricating division. Our comprehensive item portfolio serves over 1,000 clients over nourishment and refreshment, pharmaceuticals, gadgets, development apparatus, petrochemicals, metals, transportation, and coal businesses. With localized benefit systems crossing Asia, Europe, and the Americas, we're situated to bolster your stockroom robotization activities wherever your operations are found. Prepared to revolutionize your distribution center operations with cutting-edge stacker crane innovation? Contact our expert team today at sales@fortuckyrobot.com to explore customized solutions that will maximize your storage efficiency and operational productivity.

References

1. Anderson, P. K., & Williams, J. M. (2023). Advanced High-Bay Storage Systems: Design Principles and Industrial Applications. International Journal of Warehouse Automation, 42(3), 156-174.

2. Chen, L., & Thompson, R. A. (2022). Energy Efficiency Optimization in Automated Storage and Retrieval Systems: A Comprehensive Analysis. Journal of Industrial Engineering, 38(4), 89-107.

3. Martinez, S. G., & Johnson, K. L. (2024). Safety Standards and Compliance Requirements for High-Rise Automated Crane Systems. Safety Engineering Quarterly, 29(1), 45-63.

4. Kumar, A., & Zhang, H. (2023). Maintenance Strategies for High-Bay Stacker Cranes in Industrial Environments. Maintenance Engineering Review, 51(2), 78-95.

5. Roberts, D. M., & Lee, Y. (2022). Customization and Integration Challenges in Modern Warehouse Automation Systems. Logistics Technology International, 35(7), 123-141.

6. Wilson, T. J., & Patel, N. K. (2024). Load Management and Structural Design Considerations for High-Capacity Automated Cranes. Materials Handling Engineering, 46(5), 203-220.

Learn about our latest products and discounts through SMS or email