- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

manual hydraulic scissor lift

2.Featuring a scissor hydraulic mechanism, the platform enables smooth lifting and flexible movement through manual operation.

3.With load capacities covering multiple ranges from 150kg to 1500kg, it is suitable for diverse scenarios such as cargo lifting, transfer, and palletizing, meeting various operational height and spatial requirements.

Manual Hydraulic Scissor Lift - Professional Material Handling Solution

When you need efficient and reliable material handling equipment, a manual hydraulic scissor lift gets to be your culminate accomplice. Our professional-grade lifting stages provide uncommon execution for warehousing, coordinations, and generation situations. With stack capacities extending from 150kg to 1500kg and lifting statures up to 4000mm, these flexible units illuminate your most challenging fabric taking care of assignments. No power required - fair smooth, manual pressure driven operation that puts you in total control of each lift.

Why Choose Our Scissor Lift Tables?

Multi-Specification Compatibility

You get precisely what your operation needs. Our extend covers everything from lightweight 150kg units to heavy-duty 1500kg models. Whether you're dealing with little bundles or gigantic mechanical components, there's a culminate coordinate for your requirements.

Exceptional Transport Efficiency

Smart plan implies lower shipping costs for you. Our compact PT150 demonstrate permits up to 192 units per 20-foot holder, drastically diminishing your bulk buy expenses.

Flexible Manual Operation

No control outlets required. Your administrators can work anyplace with total opportunity. The compact plan fits through limit paths whereas keeping up full usefulness. One individual can effortlessly handle lifting and moving operations.

Built to Last

Reinforced steel development withstands every day mechanical utilize. Fixed oil barrels avoid defilement and guarantee steady execution. Wear-resistant wheels work discreetly, making them perfect for noise-sensitive environments.

Technical Specifications

| Model | Rated Load | Lifting Range | Worktable Dimension | Container Capacity |

|---|---|---|---|---|

| PT150 | 150kg | 210-720mm | 700×450×35mm | 192 units/20ft |

| PTS500A | 500kg | 280-850mm | 815×500×50mm | Standard shipping |

| PTD350A | 350kg | 350-1580mm | 900×700×50mm | Standard shipping |

| PTD1500 | 1500kg | 380-4000mm | 1200×610×80mm | Standard shipping |

| PTS1500 | 1500kg | 500-1700mm | 1200×610×80mm | Standard shipping |

Perfect Applications for Your Business

Warehouse Operations

Transform your capacity productivity. Lift beds to ideal working statures. Diminish laborer weariness and move forward productivity.

Production Lines

Seamlessly coordinated with your fabricating forms. Alter working statures for diverse assignments. Keep up smooth workflow without interruptions.

Loading Docks

Bridge tallness contrasts easily. Speed up stacking and emptying operations. Secure your profitable cargo amid transfers.

Maintenance Tasks

Reach hoisted gear securely. Position devices and parts at comfortable working levels. Total repairs quicker and more efficiently.

Advanced Features That Make the Difference

Precision Hydraulic Control

You control each development with smooth, responsive pressure driven activity. Fine-tune situating for sensitive operations. Keep up consistent stages indeed beneath most extreme load.

Ergonomic Design

Protect your specialists from monotonous strain wounds. Diminish lifting-related working environment mishaps. Move forward in general work fulfillment and productivity.

Maintenance-Free Operation

Minimal upkeep prerequisites keep your costs moo. Self-contained pressure driven frameworks stand up to defilement. Quality components provide a long time of dependable service.

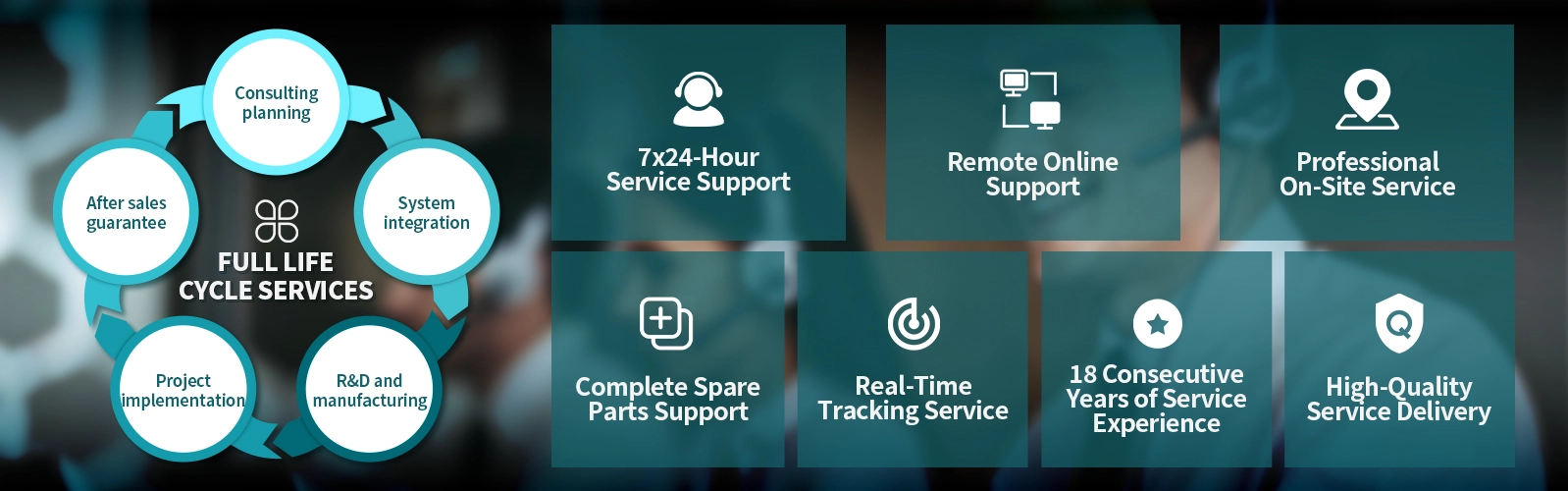

Installation and Setup

Getting started is simple. Each manual hydraulic scissor lift arrives completely collected and prepared for prompt utilize. Fundamental operation preparing takes fair minutes. Your group will be profitable from day one.

Pre-delivery review guarantees culminate condition upon entry. Comprehensive documentation guides secure operation strategies. Specialized back remains accessible at whatever point you require assistance.

Quality You Can Trust

Fortucky brings over 15 a long time of fabric taking care of ability to each unit. Our 100,000 m² fabricating office produces hardware assembly worldwide quality measures. With 360 autonomous mental property rights, we ceaselessly improve to serve you better.

Every scissor stage experiences thorough testing some time recently shipment. Quality control forms guarantee steady execution over all models. Your venture conveys tried and true benefit year after year.

Frequently Asked Questions

Q: Do lifting speeds vary across different models?

A: All models utilize manual pressure driven frameworks where you control the speed through working drive. Lifting effectiveness remains reliable over our extend, in spite of the fact that heavy-duty variations may require somewhat more exertion due to their expanded capacity.

Q: Can the work platform surface be customized?

A: Absolutely! We offer different surface alternatives counting anti-slip elastic and anti-static plates. Essentially communicate your particular prerequisites when setting your arrange, and we'll customize accordingly.

Q: What warranty coverage do you provide?

A: Core components like oil barrels and scissor structures come with a full 1-year guarantee. Wear parts such as wheels incorporate 3-month scope. We give lifetime support back for your total peace of mind.

Q: Is the 1500kg model difficult to move when fully loaded?

A: Not at all. Large-diameter, wear-resistant wheels make development easy indeed at most extreme capacity. A single administrator can effectively move the unit through limit entries without assistance.

Q: How do I determine the right model for my needs?

A: Consider your most extreme stack necessities, craved lifting tallness, and accessible workspace. Our specialized group can offer assistance you select the ideal arrangement for your particular applications.

Q: What maintenance is required?

A: Regular visual inspections and occasional lubrication of moving parts keep your equipment in perfect condition. The sealed hydraulic system requires minimal attention, making these units virtually maintenance-free.

Get Started Today

Ready to transform your material handling operations? Contact us today at sales@fortuckyrobot.com for detailed specifications and pricing information. Let our manual hydraulic scissor lift solutions elevate your productivity to new heights.

Learn about our latest products and discounts through SMS or email