- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

push back storage racks

2.Low cost, simple structure and low maintenance expenses.

3.Applied in beverage, tobacco and other industries.

4.Suitable for storing low-variety, large-quantity goods.

5.Ideal for scenarios with extremely limited storage space, while requiring large storage capacity or having low demands on goods picking.

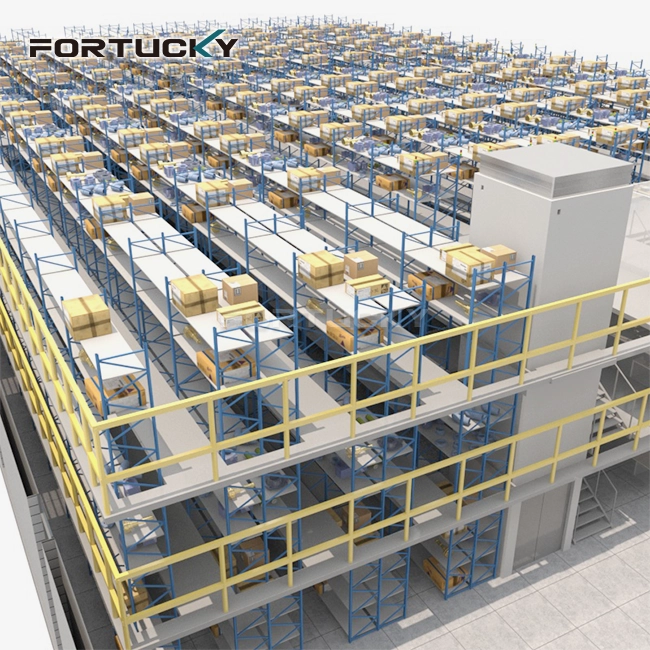

Push Back Storage Racks - High-Density Warehouse Solutions

Are you battling with constrained distribution center space whereas requiring to store expansive amounts of comparable items? Our push back storage racks offer the culminate arrangement for maximizing your capacity capacity. These inventive frameworks utilize gravity-fed innovation to make thick capacity positions with negligible passageway necessities. Not at all like conventional racking frameworks, this product allow you to store numerous beds profound whereas keeping up simple get to from a single path. This progressive plan can increment your capacity thickness by over 40% compared to customary specific racking systems.

What Are Push Back Storage Racks?

Push back capacity frameworks speak to a savvy approach to stockroom optimization. When you stack beds onto the slanted rails, each unused bed pushes the past one back along the track. Amid recovery, gravity naturally brings the following bed forward to the picking position.

This LIFO (Final In, To begin with Out) framework works superbly for putting away comparable items with congruous termination dates. The smooth operation depends on extraordinarily outlined rails and hosing gadgets that control bed movement.

Key Features & Benefits

Ultimate Space Utilization

Dense capacity positions combined with diminished passageway necessities convey uncommon space productivity. You'll accomplish much higher capacity thickness than conventional racking whereas viably lessening unit warehousing costs.

Efficient Access Operations

Forklift administrators work only at path passages without entering capacity paths. The programmed sliding component essentially moves forward warehousing operational proficiency and diminishes taking care of time.

Enhanced Safety Features

push back storage racks slide easily through accuracy hosing gadgets, anticipating collisions and falls. This plan diminishes operational requests on forklift drivers whereas giving prevalent security compared to drive-in racking alternatives.

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | High-grade Steel (Q235B) |

| Structure Type | Frame Construction |

| Maximum Height | Up to 10 meters |

| Closure Design | Open Framework |

| Application | Universal Storage |

| Adjustability | Fully Adjustable |

| Load Category | Heavy-Duty |

| Assembly | Easy Installation/Disassembly |

| Load Capacity | 1000-1500kg per level |

| Color Options | Fully Customizable |

| Dimensions | Custom Sizing Available |

| Surface Treatment | Acid Wash + Electrostatic Coating |

| Packaging | Strapping, Film, Wooden Pallets |

| Production Capacity | 150,000 tons annually |

Industries & Applications

Food & Refreshment: Culminate for putting away canned products, bottled refreshments, and bundled nourishments with reliable packaging.

Tobacco Industry: Perfect for putting away cartons and cases of tobacco items in high-volume operations.

Pharmaceuticals: Fabulous for putting away boxed solutions and therapeutic supplies with comparable rack lives.

Electronics: Reasonable for putting away bundled electronic components and wrapped up goods.

Manufacturing: Awesome for putting away crude materials and wrapped up items in bulk quantities.

Why Choose Fortucky Push Back Racks?

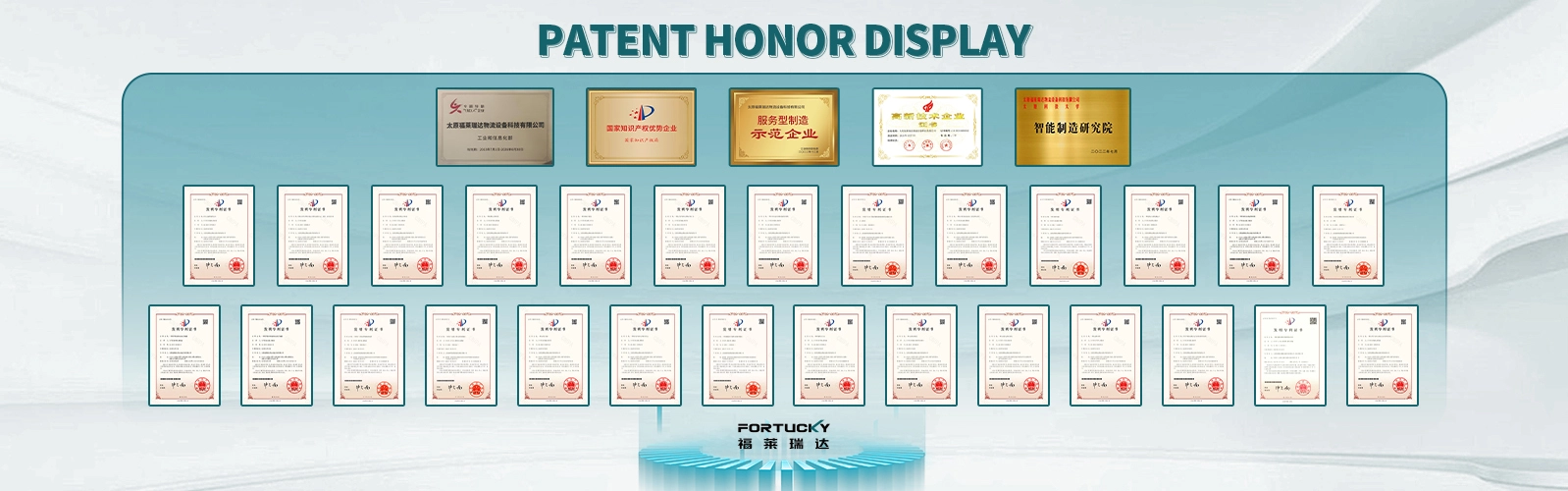

Proven Involvement: With over 1,000 fulfilled clients over Asia, Europe, and the Americas, we get it assorted capacity challenges.

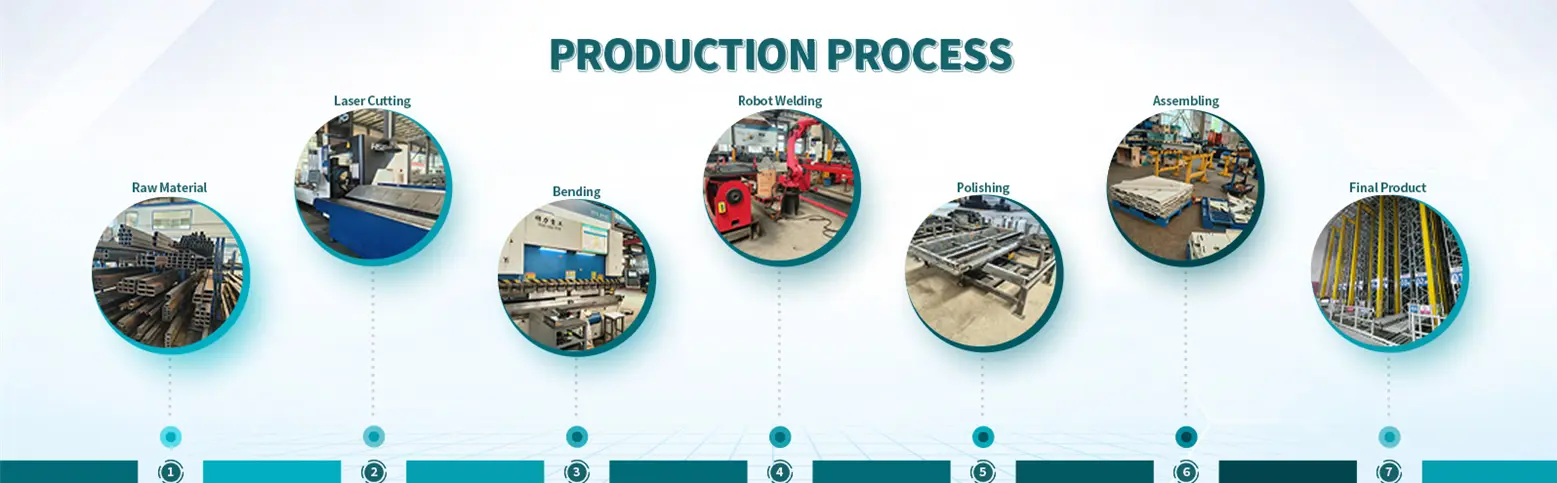

Quality Fabricating: Our 100,000 m² fabricating office produces CE-certified frameworks assembly worldwide security standards.

Custom Arrangements: Each framework is custom fitted to your particular stockroom measurements and capacity requirements.

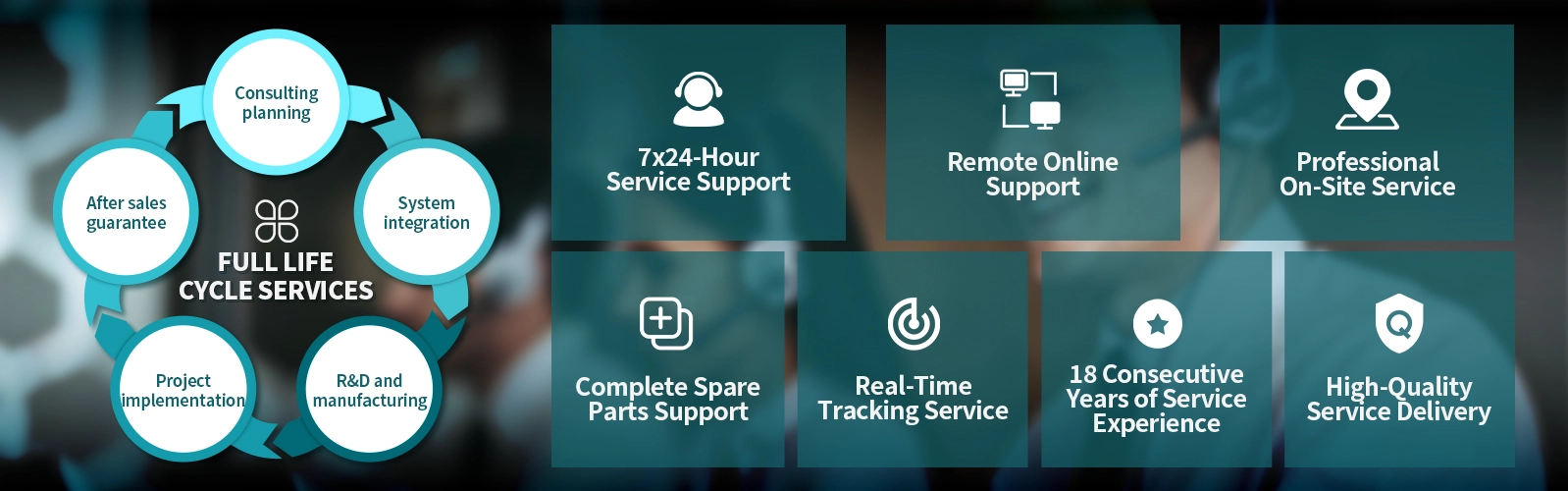

Global Back: Our 24/7 specialized back group guarantees smooth operation wherever you're located.

Cost-Effective: Diminish warehousing costs through progressed space utilization and operational efficiency.

Installation & Support

Our experienced group handles total framework plan and establishment. We give comprehensive preparing for your administrators and progressing support back to guarantee ideal performance.

Each framework incorporates point by point establishment guides and security conventions. Our measured plan permits for future extension as your capacity needs grow.

Frequently Asked Questions

Q: How do push back storage racks achieve high-density storage?

A: Through slanted tracks and hosing gadgets, beds consequently move in reverse when stacked and slide forward when recovered. This plan diminishes passageway necessities and increments capacity thickness by over 40% compared to conventional racking.

Q: What materials are used in construction?

A: We use Q235B high-grade steel for the main structure and high-strength cold-rolled steel for the rail systems. All components receive acid wash treatment plus electrostatic coating for durability and rust resistance.

Q: What's the minimum order quantity?

A: Our minimum order starts at one 20-foot container, though we can adjust based on your specific requirements.

Q: What payment methods do you accept?

A: We accept T/T wire transfer and L/C letter of credit. Standard terms require 30% advance payment with the balance due before shipment.

Q: Which product types work best with this system?

A: These racks excel with low-variety, high-volume standardized pallet goods. They're widely used in beverage, tobacco, food, and pharmaceutical industries.

Q: What's the typical production lead time?

A: Standard orders require 25-35 days for production. Rush orders can be accommodated with adjusted timelines.

Q: Do you provide samples?

A: Yes, we offer free samples for quality evaluation. Shipping costs apply separately.

Q: What's the weight capacity per level?

A: Standard capacity ranges from 1000-1500kg per level, with custom higher-capacity specifications available.

Q: What warranty do you provide?

A: We offer a comprehensive 10-year quality guarantee ensuring long-term reliable operation.

Q: How do you ensure operational safety?

A: Our frameworks incorporate movable hosing gadgets for smooth bed development, furthermore collision security and over-burden security systems.

Q: Do you offer customization options?

A: Absolutely! We provide complete customization including dimensions, colors, weight specifications, and specialized packaging solutions.

Q: How can I get a detailed proposal?

A: Simply provide your warehouse dimensions and storage requirements. We'll create a free custom solution with detailed pricing.

Get Started Today

Ready to transform your push back storage racks efficiency? Contact our team for a free consultation and custom design proposal. We'll analyze your storage requirements and provide a tailored solution that maximizes your available space.

For detailed specifications and pricing information, reach out to our experts at sales@fortuckyrobot.com. Let us help you discover how our advanced storage solutions can revolutionize your warehouse operations.

Learn about our latest products and discounts through SMS or email