- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Two Way Shuttle

2.Operation and Control: Cooperates with forklifts or stackers, controlled by remote controllers, WCS, or forklift terminals; some models support WMS integration via wireless modules.

3.Load and Speed: Load capacities include ≤1500KG (standard/high-performance/low-temperature/networked/stacker-integrated) and ≤2000KG (heavy-duty); empty speeds range from 1m/s to 1.5m/s, full speeds from 0.6m/s to 1m/s.

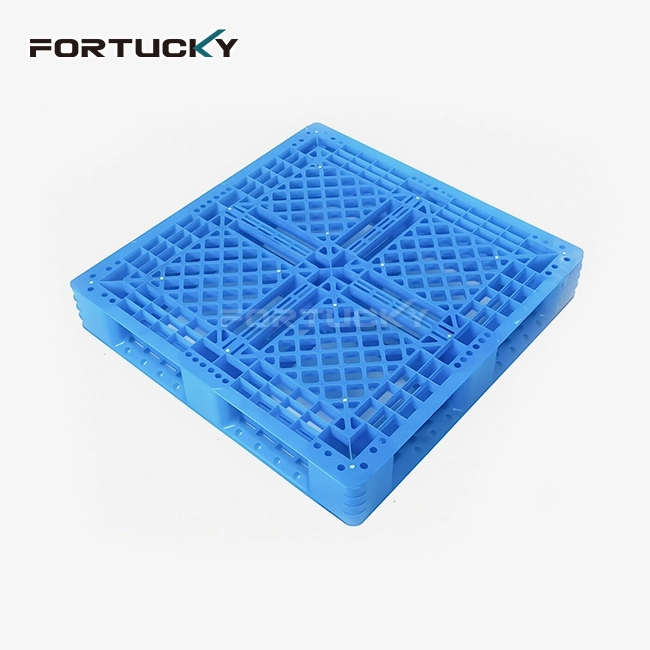

4.Applicable Pallets: Fork entry direction: 1000-1400mm.

5.Core Components: Equipped with brushless motors/drives (imported for high-performance/heavy-duty/stacker-integrated/networked), German imported laser and photoelectric sensors for precise positioning, imported custom remote controllers, and large-capacity lithium iron phosphate batteries (pure low-temperature type for low-temperature model).

6.Application Scenarios: Standard/heavy-duty/networked models for normal-temperature logistics/warehousing; low-temperature model for -25℃ environments; stacker-integrated model for automated warehouse stacker systems.

Two Way Shuttle - Advanced Automated Material Handling Solution

Are you looking to revolutionize your warehouse efficiency? Our Two Way Shuttle system offers the culminate arrangement for advanced coordinations challenges. This cleverly computerized fabric dealing with gadget works consistently with forklifts and stackers to provide extraordinary cargo capacity and recovery execution. The product represents cutting-edge innovation that changes conventional warehousing into keen, productive operations. Whether you're overseeing high-volume stock or specialized capacity prerequisites, our framework adjusts to your one of a kind needs. With different demonstrate arrangements and progressed control frameworks, you can accomplish exceptional operational proficiency whereas diminishing labor costs and making strides accuracy.

Why Choose Our Advanced Shuttle System?

Unmatched Versatility

Our carry frameworks come in six specialized setups. You get standard models for ordinary operations, high-performance units for requesting applications, and low-temperature variations for cold capacity offices. Heavy-duty models handle significant loads, whereas stacker-integrated and organized adaptations empower full automation.

Superior Performance

Experience lightning-fast operations with purge speeds coming to 1.5m/s and stacked speeds up to 1m/s. German-imported laser sensors guarantee millimeter-precise situating each time. Your operations run easily with brushless engines that convey steady, dependable performance.

Smart Integration Capabilities

Modern stockrooms require savvy arrangements. Our organized models interface straightforwardly with your WMS through remote modules. Real-time information trade optimizes stock administration and gives total operational perceivability. Integration happens consistently without disturbing existing workflows.

Built for Demanding Environments

From standard stockroom conditions to extraordinary cold capacity at -25°C, our carry frameworks perform dependably. Fixed components ensure against cruel conditions. Immaculate low-temperature batteries keep up execution indeed in cooler environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Rated Load Capacity | 1,500kg (Standard Models) / 2,000kg (Heavy-Duty) |

| Operating Speed (Empty) | 1.0 - 1.5 m/s |

| Operating Speed (Loaded) | 0.6 - 1.0 m/s |

| Pallet Compatibility | Fork entry direction: 1,000-1,400mm |

| Power System | Lithium iron phosphate battery |

| Control Options | Remote controller, WCS, Forklift terminal |

| Advanced Features | WMS docking (networked models) |

| Temperature Range | -25°C to +40°C (model dependent) |

| Positioning System | German imported laser sensors |

| Motor Type | Brushless motors (imported for premium models) |

Key Advantages That Set Us Apart

Multiple Model Configurations

Choose from six particular models custom-made to particular applications. Standard and heavy-duty models exceed expectations in ordinary temperature situations. Low-temperature models flourish in cold capacity offices. Organized and stacker-integrated forms empower total stockroom automation.

Precision Engineering

German-imported sensors convey extraordinary exactness in situating and route. Brushless engines give smooth, proficient operation with negligible support prerequisites. Each component experiences thorough testing to guarantee long-term reliability.

Smart Control Systems

Operate through inaccessible controllers for manual control or coordinated with distribution center control frameworks for computerized operations. Organized models bolster coordinate WMS communication, empowering real-time stock following and robotized decision-making.

Exceptional Durability

Lithium press phosphate batteries offer expanded operational life and steady execution. Fixed components ensure against tidy, dampness, and temperature varieties. Premium materials guarantee a long time of trouble-free operation.

Applications Across Industries

Our carry frameworks serve different businesses with specialized necessities. Nourishment and refreshment companies advantage from our low-temperature models in cold capacity offices. Hardware producers appreciate accuracy taking care of of touchy components. Pharmaceutical companies depend on our clean, exact operations for basic stock management.

Manufacturing offices utilize heavy-duty models for strong materials dealing with. Conveyance centers use organized frameworks for high-volume arrange fulfillment. The Two Way Shuttle adjusts to your particular operational necessities whereas keeping up steady execution standards.

Implementation and Support

Fortucky's experienced group guarantees smooth usage from arranging through commissioning. Our secluded plan empowers fast sending with negligible operational disturbance. Comprehensive preparing programs plan your group for ideal framework utilization.

Global bolster administrations give 24/7 specialized help at whatever point you require it. Farther checking capabilities permit proactive support planning. Nearby benefit groups react rapidly to any bolster requirements.

Frequently Asked Questions

Q: What exactly is this equipment?

A: Our framework is an robotized fabric dealing with gadget planned to work with forklifts and stackers for proficient stockroom capacity and recovery operations.

Q: What load capacities are available?

A: We offer models with capacities up to 1,500kg for standard applications and 2,000kg for heavy-duty requirements.

Q: What are the key component advantages?

A: Our frameworks include imported brushless engines, German laser sensors for exact situating, long-lasting lithium press phosphate batteries, and fixed components for reliability.

Q: How do you control the system?

A: Control alternatives incorporate farther controllers, distribution center control frameworks, and forklift terminals. Progressed models back coordinate WMS integration for total automation.

Q: What environments can it operate in?

A: Standard models work in normal warehouse conditions, while specialized low-temperature models operate in environments as cold as -25°C. Heavy-duty models handle demanding industrial applications.

Q: What are the speed specifications?

A: Empty operation speeds range from 1.0-1.5 m/s, while loaded speeds reach 0.6-1.0 m/s. The system accommodates pallets with fork entry directions from 1,000-1,400mm.

Q: What special features are available?

A: Special features include full low-temperature sealing for cold storage applications and wireless modules for WMS integration, ensuring adaptability to diverse operational requirements.

Ready to Upgrade Your Operations?

Transform your warehouse into a smart, efficient operation with our advanced shuttle systems. Contact our experts today to discuss your specific requirements and discover how the Two Way Shuttle can revolutionize your logistics operations.

Get in touch: sales@fortuckyrobot.com

Learn about our latest products and discounts through SMS or email