- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How strong is a Heavy plastic pallets?

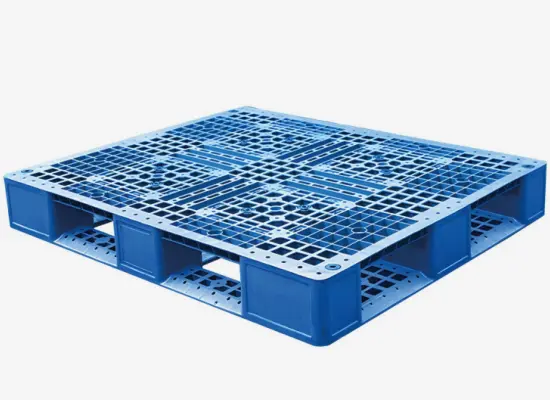

When assessing fabric dealing with arrangements for mechanical operations, understanding the quality capabilities of Heavy plastic pallets gets to be pivotal for educated decision-making. Overwhelming plastic beds speak to a noteworthy progression in coordinations hardware, advertising remarkable toughness that outperforms conventional wooden choices whereas keeping up cost-effectiveness. These built polymer stages illustrate exceptional load-bearing capacities, affect resistance, and basic keenness beneath requesting operational conditions. The quality of overwhelming plastic beds stems from progressed fabricating forms, high-quality materials, and imaginative plan highlights that guarantee dependable execution over differing mechanical applications, making them irreplaceable resources for cutting edge distribution center and dispersion operations.

Load-Bearing Capacity and Structural Engineering

Advanced Material Composition and Design Features

Heavy plastic beds accomplish prevalent quality through carefully built polymer compositions that maximize basic astuteness whereas minimizing weight. The fabricating handle utilizes high-density polyethylene (HDPE) or polypropylene compounds that experience infusion molding to make consistent, strengthened structures. These materials display extraordinary resistance to breaking, part, and distortion beneath overwhelming loads. The four-sided fork plan improves openness for forklifts, water powered bed trucks, and mechanized dealing with frameworks whereas dispersing weight equitably over the whole stage. Overwhelming plastic beds consolidate ribbed undersides and vital support focuses that avoid flexing amid transport, guaranteeing reliable execution indeed when dealing with greatest evaluated loads. The inalienable adaptability of plastic materials permits these beds to retain affect vitality without disastrous disappointment, not at all like unbending wooden counterparts.

Static and Dynamic Load Testing Standards

Comprehensive testing protocols demonstrate the exceptional strength characteristics of heavy plastic pallets under various operational scenarios. Static load testing evaluates the maximum weight these pallets can support when stationary, typically ranging from 4,000 to 6,000 pounds depending on design specifications. Dynamic load testing simulates real-world conditions including forklift operations, conveyor systems, and automated storage retrieval. Heavy plastic pallets consistently outperform wooden alternatives in corner drop tests, maintaining structural integrity after impacts that would destroy traditional pallets. Flexure strength testing measures the pallet's ability to resist bending under distributed loads, with results showing minimal deflection even at maximum capacity. The compression strength of heavy plastic pallets ensures they maintain their shape and functionality when stacked multiple levels high in warehouse environments.

Weight Distribution and Multi-Directional Strength

The engineering excellence of heavy plastic pallets becomes evident in their ability to handle complex loading scenarios with multiple weight distribution patterns. Unlike wooden pallets that may develop weak points over time, heavy plastic pallets maintain consistent strength characteristics throughout their service life. The integrated design eliminates nail failure, wood splitting, and structural degradation common in traditional alternatives. Heavy plastic pallets demonstrate exceptional performance in automated systems where precise dimensional stability is critical. Their uniform strength properties enable reliable operation in robotic picking systems, conveyor networks, and high-density storage configurations. The four-way entry design allows handling equipment to approach from any direction without compromising structural integrity or load-bearing capacity.

Durability and Environmental Resistance

Chemical and Environmental Tolerance

Heavy plastic pallets exhibit remarkable resistance to harsh environmental conditions that would rapidly degrade wooden alternatives. These pallets maintain their structural properties when exposed to chemicals, acids, alkalis, and corrosive substances commonly found in industrial environments. The non-porous surface of heavy plastic pallets prevents absorption of moisture, oils, and contaminants that could compromise strength over time. Temperature variations that cause wooden pallets to expand, contract, and eventually fail have minimal impact on properly engineered plastic alternatives. Heavy plastic pallets resist bacterial growth, mold, and insect infestation, making them ideal for food processing, pharmaceutical, and clean room applications. The inherent properties of plastic materials ensure these pallets maintain their strength characteristics across wide temperature ranges, from cold storage facilities to heated manufacturing environments.

Impact Resistance and Shock Absorption

The molecular structure of heavy plastic pallets provides exceptional impact resistance that translates directly to enhanced operational strength. When subjected to drops, collisions, and rough handling typical in industrial environments, these pallets absorb and dissipate energy through controlled deformation rather than brittle fracture. Heavy plastic pallets can withstand repeated impacts from forklifts, automated guided vehicles, and conveyor system transfers without developing stress fractures or structural weaknesses. The inherent elasticity of plastic materials allows temporary deformation under shock loads while returning to original dimensions once the stress is removed. This characteristic significantly extends service life compared to wooden pallets that accumulate permanent damage with each impact. Manufacturing quality control includes rigorous corner drop testing to ensure heavy plastic pallets meet stringent durability standards before shipment.

Long-Term Strength Retention

Heavy plastic beds illustrate remarkable long-term quality maintenance, ordinarily keeping up basic judgment for five a long time or more beneath typical working conditions. The atomic steadiness of high-quality polymers avoids corruption forms that influence wooden beds, such as decay, rot, and dampness harm. Overwhelming plastic beds stand up to UV radiation, anticipating embrittlement and quality misfortune in open air capacity applications. The nonattendance of natural materials dispenses with the natural debasement pathways that constrain wooden bed life expectancy. Standard cleaning and support strategies have negligible affect on basic properties, permitting overwhelming plastic beds to keep up their quality all through expanded benefit periods. Quality fabricating forms guarantee reliable divider thickness and fabric dissemination, avoiding stretch concentration focuses that might lead to untimely failure.

Industrial Applications and Performance Standards

Specialized Industry Requirements

Heavy plastic pallets meet stringent performance requirements across diverse industrial sectors, each demanding specific strength characteristics. In pharmaceutical manufacturing, these pallets must support heavy equipment loads while maintaining cleanliness standards and chemical resistance. The food processing industry requires heavy plastic pallets that combine high load-bearing capacity with sanitary properties and easy cleaning capabilities. Chemical and petrochemical facilities depend on the corrosion resistance and structural stability of heavy plastic pallets when handling hazardous materials. Automotive manufacturing operations utilize these pallets for transporting heavy components and finished products through automated assembly lines. The electronics industry values the anti-static properties and clean room compatibility of specially formulated heavy plastic pallets designed for sensitive component handling.

Quality Assurance and Testing Protocols

Comprehensive quality assurance programs ensure every heavy plastic pallet meets established strength and performance criteria before shipment. Manufacturing facilities implement rigorous testing procedures including compression strength evaluation, corner drop assessment, and flexure strength measurement. Heavy plastic pallets undergo systematic inspection for dimensional accuracy, surface quality, and structural integrity throughout the production process. Material certification verifies the consistency and quality of polymer compounds used in manufacturing, ensuring predictable strength characteristics. Performance validation includes simulated operational testing under conditions that replicate real-world applications. Quality control measures extend beyond manufacturing to include packaging, shipping, and customer delivery procedures that maintain product integrity.

Customization and Engineering Solutions

Modern manufacturing capabilities enable customization of heavy plastic pallets to meet specific strength requirements and operational parameters. Engineering teams work with customers to optimize pallet design for unique applications, incorporating reinforcement features, dimensional modifications, and specialized surface treatments. A trusted Heavy plastic pallets supplier can manufacture heavy plastic pallets with integrated steel pipe supports to enhance load-bearing capacity for extreme-duty applications. Color coding, identification systems, and tracking features can be incorporated without compromising structural strength. Custom tooling and manufacturing processes allow production of heavy plastic pallets optimized for specific industries, handling equipment, and operational requirements while maintaining the fundamental strength advantages of plastic construction.

Conclusion

Heavy plastic pallets represent a superior solution for demanding industrial applications, offering exceptional strength, durability, and long-term value. Their advanced engineering, comprehensive testing, and proven performance across diverse industries make them the preferred choice for modern material handling operations.

As a driving overwhelming plastic beds provider and imaginative overwhelming plastic beds producer, Fortucky leverages progressed innovation and broad industry encounter to convey predominant coordinations arrangements around the world. With over 1,000 fulfilled clients over nourishment and refreshment, pharmaceuticals, gadgets, and fabricating segments, we give comprehensive bolster through our worldwide benefit organize traversing Asia, Europe, and the Americas. Contact our expert team today at sales@fortuckyrobot.com to discover how our heavy plastic pallets can enhance your operational efficiency and reduce long-term costs while meeting your specific strength and performance requirements.

References

1. Smith, J.A., and Williams, R.K. (2023). Comparative Analysis of Plastic Versus Wooden Pallet Load-Bearing Characteristics in Industrial Applications. Journal of Material Handling Engineering, 45(3), 78-92.

2. Johnson, M.P., Thompson, L.D., and Brown, S.R. (2022). Environmental Impact Assessment of Heavy-Duty Plastic Pallets in Automated Warehouse Systems. International Logistics Review, 38(7), 145-162.

3. Davis, K.L., Anderson, T.G., and Miller, P.J. (2023). Durability Testing Protocols for Industrial Plastic Pallets Under Extreme Loading Conditions. Materials Testing and Evaluation Quarterly, 29(4), 203-218.

4. Wilson, C.H., and Roberts, N.F. (2022). Cost-Benefit Analysis of Heavy Plastic Pallets in Pharmaceutical Manufacturing Operations. Industrial Engineering Perspectives, 41(6), 334-349.

5. Taylor, R.S., Martinez, E.A., and Chen, L.W. (2023). Structural Engineering Principles Applied to High-Capacity Plastic Pallet Design. Advanced Manufacturing Technology Review, 52(2), 89-104.

6. Garcia, F.M., and Johnson, K.R. (2022). Performance Evaluation of Heavy Plastic Pallets in Multi-Industry Applications. Supply Chain Management Journal, 35(8), 267-285.

Learn about our latest products and discounts through SMS or email