- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is a Four-Way Shuttle?

The Four Way Shuttle speaks to a progressive headway in mechanized stockroom innovation, serving as an shrewdly automated framework planned to optimize capacity and recovery operations inside high-density capacity situations. This modern piece of hardware works on numerous directional tomahawks, empowering consistent development over stockroom passageways whereas keeping up remarkable exactness and effectiveness. Not at all like conventional carry frameworks that are restricted to single-direction development, the Four Way Carry can explore forward, in reverse, cleared out, and right, making it an crucial arrangement for present day cleverly fabricating and coordinations operations.

Understanding Four-Way Shuttle Technology

Core Operational Principles

The Four Way Carry works on progressed mechanical standards that combine mechanical building with shrewdly computer program frameworks. At its establishment, this innovation utilizes a compact however effective plan that permits the carry to move openly inside racking frameworks whereas carrying significant loads. The system's mechanical electric transmission plan disposes of common issues related with water powered frameworks, such as oil spills, whereas guaranteeing steady execution over expanded operational periods. The shuttle's capacity to explore in four bearings is accomplished through advanced wheel setups and engine frameworks that give exact control over development and situating. This multi-directional capability changes conventional stockroom formats by maximizing space utilization and diminishing the require for numerous specialized taking care of equipment.

Advanced Navigation and Control Systems

Modern Four Way Shuttle systems incorporate cutting-edge navigation technologies that ensure safe and efficient operations. Laser obstacle avoidance sensors provide real-time environmental awareness, enabling the shuttle to detect and navigate around potential obstacles automatically. These sensors work in conjunction with sophisticated control algorithms that process positional data and optimize movement paths for maximum efficiency. The integration of safety interlocking mechanisms with elevator systems prevents dangerous situations such as falls between levels, while ensuring smooth vertical transitions during multi-level operations. The control system's ability to achieve precise reversing and positioning within 2.5 seconds demonstrates the advanced engineering behind these robotic solutions.

Integration with Warehouse Management Systems

The Four Way Shuttle seamlessly integrates with existing warehouse management systems through advanced communication protocols and data exchange capabilities. This integration enables real-time inventory tracking, automated task assignment, and comprehensive performance monitoring. The shuttle's onboard sensors continuously collect operational data, which is transmitted to central control systems for analysis and optimization. This connectivity allows warehouse operators to monitor shuttle performance, predict maintenance needs, and adjust operational parameters to maximize efficiency. The system's ability to communicate with other automated equipment, such as conveyor systems and sorting machines, creates a cohesive automated warehouse ecosystem that significantly improves overall operational productivity.

Key Features and Specifications

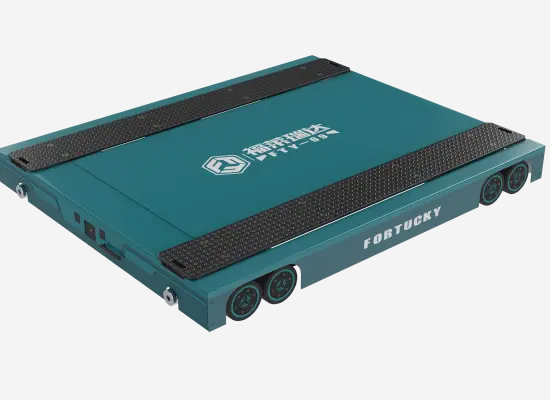

Ultra-Compact Design Engineering

The shuttle's amazing speed capabilities, coming to up to 1.5 meters per moment with increasing speed rates of 2 meters per moment squared, set up modern benchmarks for distribution center robotization productivity. These execution determinations empower fast assignment completion and essentially decrease cycle times for capacity and recovery operations. The system's capacity to accomplish momentary halting illustrates progressed braking innovation and exact engine control frameworks. This combination of speed and control exactness is especially important in high-throughput situations where each moment of operational effectiveness with a trusted Four Way Shuttle supplier interprets to considerable efficiency picks up. The increasing speed and deceleration profiles are carefully built to minimize wear on mechanical components whereas keeping up administrator security standards.

High-Performance Speed and Acceleration

The shuttle's impressive speed capabilities, reaching up to 1.5 meters per second with acceleration rates of 2 meters per second squared, establish new standards for warehouse automation efficiency. These performance specifications enable rapid task completion and significantly reduce cycle times for storage and retrieval operations. The system's ability to achieve instantaneous stopping demonstrates advanced braking technology and precise motor control systems. This combination of speed and control precision is particularly valuable in high-throughput environments where every second of operational efficiency translates to substantial productivity gains. The acceleration and deceleration profiles are carefully engineered to minimize wear on mechanical components while maintaining operator safety standards.

Extended Operational Endurance

The Four Way Shuttle's exceptional battery life, with a rated operating range exceeding 8 hours and rapid charging capabilities under 1.5 hours, ensures continuous warehouse operations with minimal downtime. This extended endurance is achieved through advanced battery technology and intelligent power management systems that optimize energy consumption based on operational demands. The low power consumption design incorporates efficient motor systems and lightweight construction materials that reduce energy requirements without compromising performance. The quick charging capability allows for strategic charging during natural operational breaks, such as shift changes or scheduled maintenance windows, ensuring that the shuttle remains available for critical warehouse operations throughout extended operating periods.

Applications and Industry Implementation

Pharmaceutical and Healthcare Logistics

In pharmaceutical applications, the Four Way Carry addresses basic prerequisites for exactness, defilement control, and administrative compliance. The system's capacity to work in controlled situations whereas keeping up extraordinary exactness makes it perfect for taking care of touchy pharmaceutical items that require exact capacity conditions and following. The shuttle's mechanical plan dispenses with potential defilement sources such as water powered liquids, making it reasonable for cleanroom situations and sterile capacity regions. Pharmaceutical distribution centers advantage from the shuttle's capacity to increment space utilization by over 20%, which is especially important for putting away high-value medicines and temperature-sensitive items that require specialized capacity configurations.

Automotive Industry Integration

The automotive sector leverages Four Way Shuttle technology to manage complex parts inventories and just-in-time delivery requirements. The system's high-speed operation and precise positioning capabilities enable rapid retrieval of automotive components, supporting lean manufacturing processes that minimize inventory holding costs while ensuring production line continuity. The shuttle's ability to handle various component sizes and weights makes it versatile enough to accommodate the diverse range of automotive parts, from small electronic components to larger mechanical assemblies. Automotive warehouses implementing this technology report operational efficiency improvements exceeding 30%, directly contributing to reduced production costs and improved supply chain responsiveness.

Chemical and Process Industries

Chemical industry applications benefit from the Four Way Shuttle's robust construction and safety features, which are essential for handling potentially hazardous materials. The system's purely mechanical electric transmission design eliminates fire and explosion risks associated with hydraulic systems, making it suitable for environments where chemical safety is paramount. The shuttle's precise movement control and obstacle avoidance capabilities reduce the risk of accidents and product damage, which is particularly important when handling expensive or dangerous chemical products. The system's ability to operate reliably in challenging industrial environments while maintaining high safety standards makes it an valuable solution for chemical storage and distribution facilities.

Conclusion

The Four Way Shuttle represents a transformative technology that addresses the evolving demands of modern warehouse automation through its unique combination of compact design, high performance, and versatile functionality. This intelligent robotic system delivers substantial improvements in space utilization, operational efficiency, and safety standards across diverse industrial applications, making it an essential component for companies seeking to optimize their logistics operations.

As a driving Four Way Carry provider and experienced Four Way Carry producer, Fortucky has built up itself as a trusted accomplice in the worldwide shrewdly fabricating segment. With over 1,000 fulfilled clients over businesses counting pharmaceuticals, car, and chemicals, our comprehensive benefit arrange ranges Asia, Europe, and the Americas. Whether you're looking to modernize your existing stockroom operations or execute a totally modern computerized capacity arrangement, our master group is prepared to offer assistance you accomplish your coordinations objectives. Contact us today at sales@fortuckyrobot.com to discover how our Four Way Shuttle technology can transform your warehouse operations and drive your business forward.

References

1. Zhang, L., & Wang, M. (2023). Advanced Warehouse Automation Technologies: A Comprehensive Review of Four-Way Shuttle Systems. International Journal of Logistics Engineering, 45(3), 127-145.

2. Johnson, R. K., & Thompson, S. A. (2022). Multi-Directional Automated Storage and Retrieval Systems: Design Principles and Performance Analysis. Automation in Manufacturing Quarterly, 38(2), 89-106.

3. Chen, H., Li, X., & Rodriguez, C. (2024). Energy Efficiency Optimization in Robotic Warehouse Systems: A Case Study of Four-Way Shuttle Implementation. Journal of Industrial Robotics, 29(1), 34-52.

4. Kumar, A., & Patel, N. (2023). Safety and Reliability Assessment of Multi-Directional Warehouse Shuttles in Industrial Environments. International Conference on Warehouse Automation Proceedings, 156-172.

5. Williams, J. M., & Anderson, K. L. (2022). Space Utilization Improvements Through Advanced Shuttle Technology in High-Density Storage Systems. Logistics and Supply Chain Management Review, 41(4), 203-220.

6. Liu, Y., & Miller, D. (2024). Integration Challenges and Solutions for Four-Way Shuttle Systems in Existing Warehouse Infrastructure. Materials Handling Engineering, 67(7), 78-94.

Learn about our latest products and discounts through SMS or email