- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Mesh Storage Transport Cage

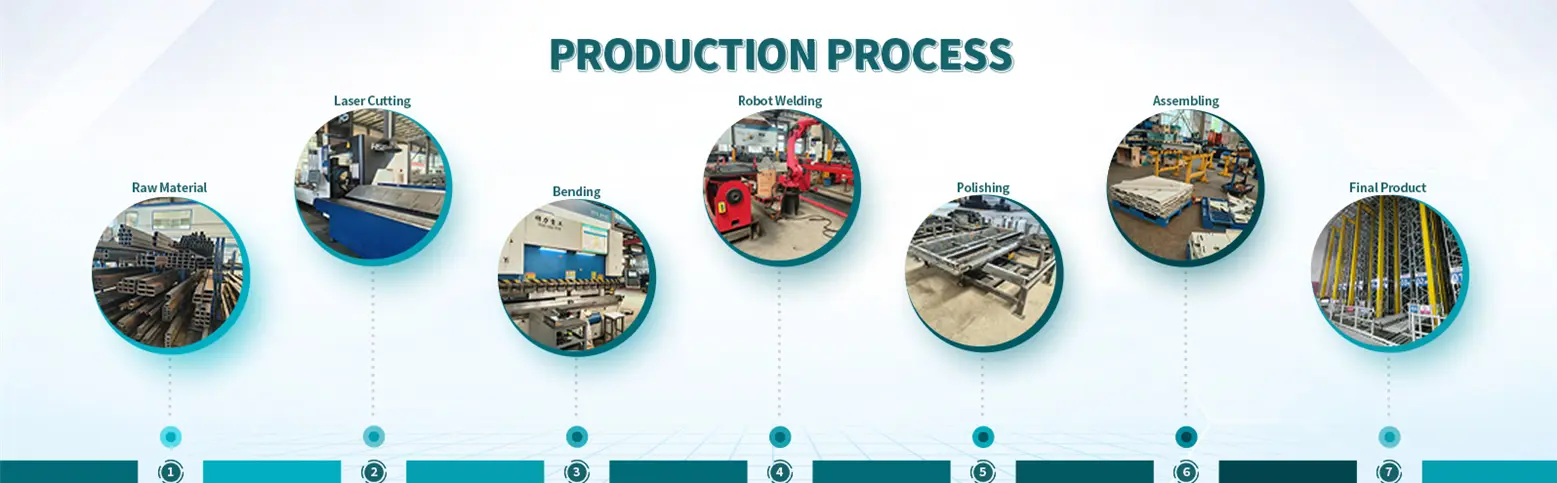

2.The open mesh structure ensures ventilation, visibility and ease of inventory management, making it an ideal choice for factories, logistics centers, supermarkets, etc.

3.Special folding design, very convenient. It is easy to fold and unfold, occupies no space, has a wide range of applications and a long lifespan.

4.Combined with a dedicated tripod, it is sturdy and durable, making the work safer and more efficient. The factory's actual departments find it the most advantageous and convenient transfer equipment.

Mesh Storage Transport Cage - Efficient Modular Storage Solution

Looking for a reliable storage solution that maximizes your warehouse efficiency? The Mesh Storage Transport Cage is your reply to present-day coordination challenges. This inventive capacity framework combines high-strength metalwork development with a keen foldable plan, making it ideal for manufacturing plants, coordination centers, and general stores. Whether you're overseeing stock in an active dispersion center or organizing components in fabricating offices, our product delivers unmatched flexibility and solidness for your capacity needs.

Why Choose Our Storage Cages?

Superior Design Features

Our storage cages include a welded metalwork structure that's both lightweight and unimaginably solid. The open framework plan gives you total perceivability of your stock at all times. You can effortlessly check stock levels without opening holders, making stock administration quicker and more accurate.

The foldable plan is a game-changer for your operations. When purged, these cages overlay the level and spare over 90% of capacity space. This implies lower return shipping costs and negligible capacity prerequisites when not in use.

Built for Heavy-Duty Performance

Each Mesh Storage Transport Cage is developed from high-strength Q235 steel with proficient welding methods. The vigorous outline handles requesting stockroom situations while keeping up basic keenness. Our electrostatic powder coating gives amazing erosion resistance, guaranteeing long-lasting execution in different conditions.

Flexible Configuration Options

You can customize measurements, layer statures, and add extra highlights to coordinate your particular needs. Include casters for portable capacity arrangements, or introduce lockable entryways for secure capacity. The secluded plan adjusts to your changing requirements.

Key Benefits for Your Operations

Space Optimization: Stack numerous filled cages safely to twofold your vertical capacity. The stackable plan maximizes distribution center space utilization.

Improved Productivity: Forklift-compatible plan permits access from all sides. This speeds up stacking and emptying operations significantly.

Visual Administration: The work structure empowers speedy visual stock checks. You'll minimize stock inconsistencies and move forward accurately.

Cost Reserve funds: Decreased capacity and transportation costs when cages are collapsed. Lower labor costs due to less demanding taking care of and organization.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | Mesh Storage Transport Cage |

| Main Material | Q235 Steel |

| Surface Treatment | Powder Coating |

| Standard Capacity | 500kg / 1000kg |

| Closure Type | Snap-on Hook System |

| Assembly Status | Ready-to-Use (Pre-assembled) |

| Customization | Size, Color, Capacity Available |

| Main Function | Foldable & Stackable |

| Application | Warehouse Storage Systems |

Applications Across Industries

These flexible cages serve numerous businesses effectively:

- Manufacturing: Component capacity and work-in-progress organization

- Logistics Centers: Conveyance and sorting operations

- Retail: Back-of-house stock management

- Automotive: Parts capacity and gathering line supply

- Food & Refreshment: Dry products and bundling fabric storage

Frequently Asked Questions

Q: Where can I use these storage cages?

A: These cages are idealized for fabricating component stockrooms, coordinating conveyance centers, increasing grocery store dry products capacity, and any office requiring standardized capacity arrangements. They're basic hardware for effective stockroom capacity systems.

Q: What weight capacity options are available?

A: We offer adaptable capacity alternatives. Standard cages hold 500 kilograms, whereas strengthened models bolster up to 1000 kilograms to suit distinctive capacity requirements.

Q: How do the foldable and stackable features work?

A: When purged, cages overlap level like a collapsing box, lessening space by over 90%. This spares noteworthy costs for return transportation and capacity. When filled, numerous cages stack safely utilizing security locks, maximizing vertical stockroom space.

Q: What advantages does the mesh design provide?

A: The open work plan offers three key benefits: amazing ventilation for moisture-sensitive things, total perceivability for stock administration without opening holders, and forklift access from all sides for effective handling.

Q: What customization options do you offer?

A: We give broad customization counting measurements (length, width, and tallness), work with various work thicknesses, lockable entryways, settled or swivel casters for portability, and different surface treatment colors.

Q: How durable are these cages?

A: The cage body uses high-strength Q235 steel with professional welding for solid construction. Electrostatic powder coating provides excellent anti-corrosion protection, ensuring durability in demanding warehouse and workshop environments.

Q: Do I need to assemble the cages myself?

A: No assembly required! Our storage cages ship fully assembled and ready to use immediately upon delivery. This saves you time and eliminates complex installation procedures.

Q: Are these cages forklift-compatible?

A: Absolutely! Standard cages feature forklift access holes at the bottom, allowing easy extraction and handling from all directions. This makes them ideal for unitized handling operations connecting warehousing and transportation.

Q: How do the closure mechanisms work?

A: We use reliable hook-type closures that are quick and simple to operate while providing secure locking. During normal stacking and handling, these closures prevent accidental opening, ensuring cargo safety.

Get Started Today

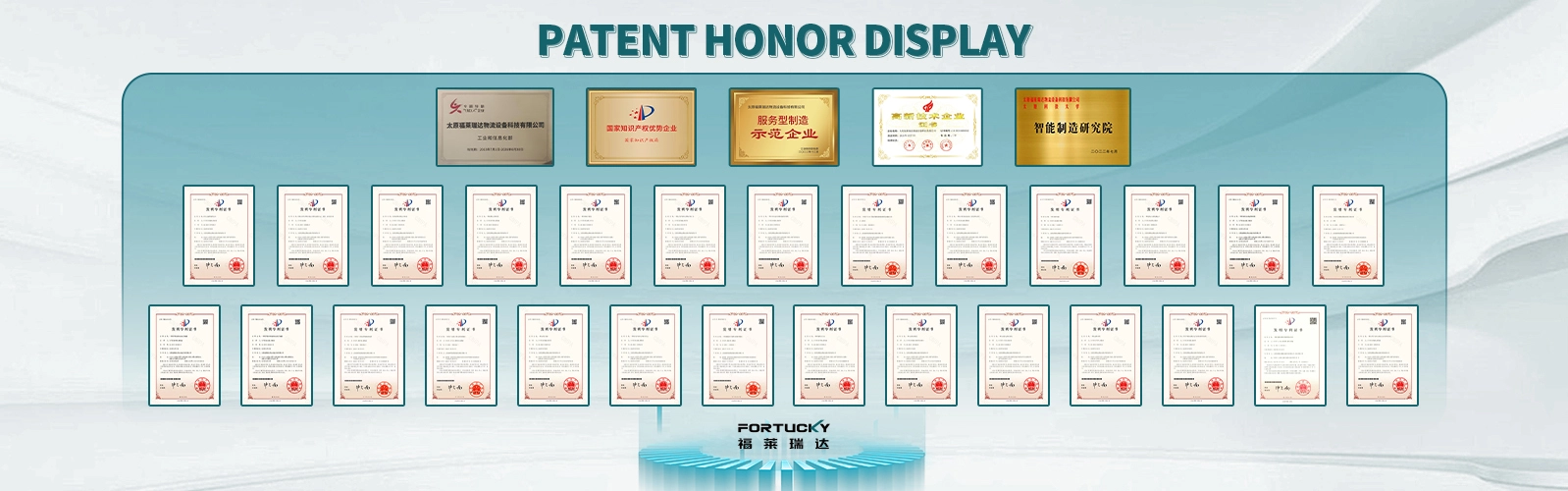

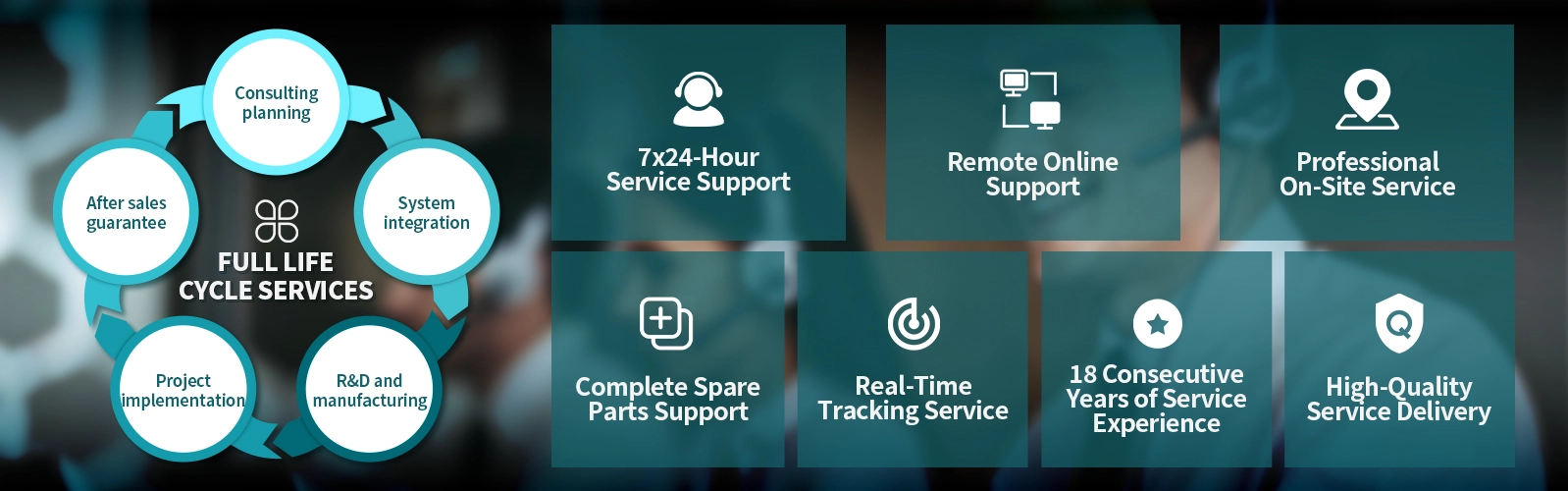

Transform your warehouse operations with our Mesh Storage Transport Cage solutions. Our experienced team at Fortucky has served over 1,000 customers worldwide, delivering reliable storage solutions that improve efficiency and reduce costs.

Ready to optimize your storage system? Contact our team at sales@fortuckyrobot.com to discuss your specific requirements and receive a customized quote. Let us help you build a more efficient, organized, and profitable warehouse operation.

Learn about our latest products and discounts through SMS or email